Genesis

In the context of Internet of Things (IoT) that are taking a new step with Industry 4.0, instrumentation still plays a major role. In direct link with the machines or their close environment, sensors allow a monitoring of the operation and its external conditions in order to optimize and perpetuate the production tool.

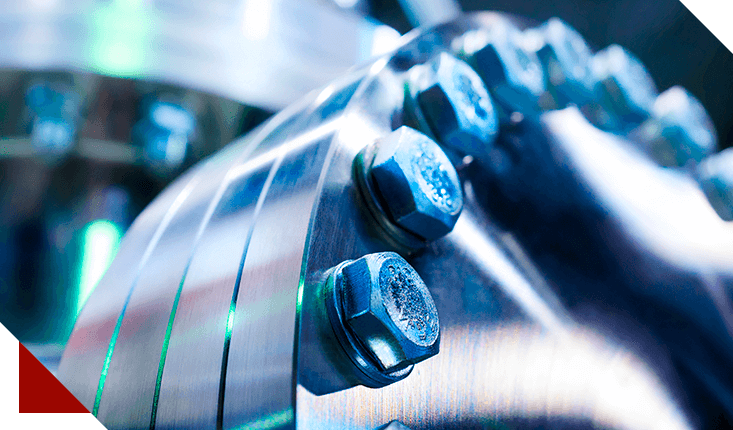

On bolted assemblies, the tightening means install the recommended preload and the instrumented and connected screws ensure the monitoring in service. These are no longer reserved solely for the qualification stages, but also find their place among the control and monitoring applications.

In order to respond to these evolutions, TEXYS Group initiated in 2012 the development of the TM-FAST® solution for an application in the aeronautical sector. The idea came from our founder, Etienne Deméocq, and our CEO, Philippe Leuwers, to instrument a screw with strain gauges, capitalizing on all our know-how in this field for over 20 years through our flagship brand TEXENSE®.

TEXYS Group, specialist in physical measurement solutions and embedded sensors in constrained environments, brings you TM-FAST®: TEXENSE® Monitoring Fastener, our innovative and patented solution based on instrumented bolts for connected assemblies, intended for 2 main and complementary applications:

- Monitoring of fastening loads

- Preventive maintenance

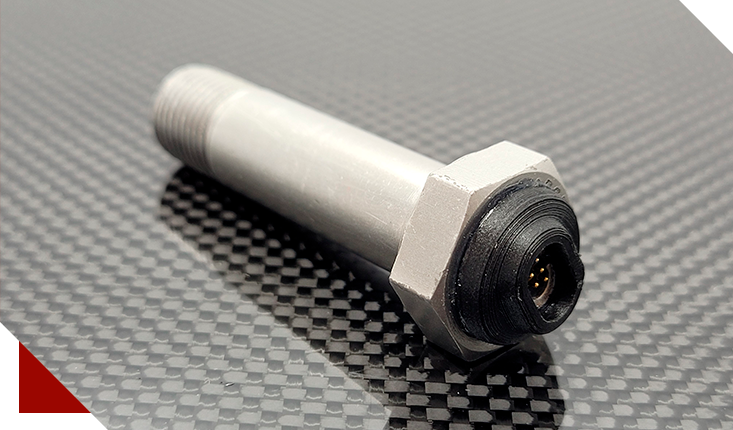

The main interest is to leave the mechanical characteristics of the screw intact while allowing a practical and direct access to the measurement. Our TM-FAST® technology is patented in Europe, USA, China, and Japan. It is based on:

- A machining of the screw head with unchanged mechanical properties

- A design of specific strain gauges for installation in the screw head

TM-FAST® solution overview

TEXYS Group offers you TM-FAST®, our complete monitoring solution, from initial fastening to preventive maintenance through instrumented bolts for connected assemblies.

The main advantage is that it does not modify the mechanical characteristics of the screw while allowing convenient and direct access to the measurement. This patented solution has been validated on parts with diameters from M4 to M33, with the aim of instrumenting any type of screw.

Depending on your application, whether on a test bench or on-site, TEXYS Group will provide the most suitable TM-FAST® solution.

We currently offer 2 technological variants of TM-FAST® (C, WL) to meet the exact needs of our customers. Other options are under study, always responding to the needs expressed by our customers.

With TM-FAST®, you benefit from a complete solution:

- Fastening: a measurement of the clamping load during the initial fastening and an adjustment based on your specifications

- Monitoring: a follow-up of the fastening of each instrumented bolt, at a frequency defined according to your needs and possible readjustment with the values obtained

- Preventive maintenance: monitoring of the evolution of the tension in the assembly over time

Fastening

Fastening

Monitoring

Monitoring

Preventive maintenance

Preventive maintenance

Targetted industries

Based on 25 years of experience, TEXYS Group brings forward the TM-FAST® solution for all types of industries, which can be adapted to a multitude of applications requiring the monitoring of fastening loads and preventive maintenance of infrastructures.